Understanding the unique characteristics of the materials used in your remodel

As part of our commitment to transparency and quality, we want to highlight a few important things to know about the materials commonly used in residential remodeling.

Many of the products we work with—such as natural stone, hardwood, and handcrafted tile—are selected for their beauty, character, and uniqueness. But with that comes natural variation and certain performance traits that are important to understand before installation begins.

This page is designed to help set expectations and provide clarity on how these materials behave in real-world applications. Our goal is to help you feel confident in your selections and enjoy the finished product for years to come.

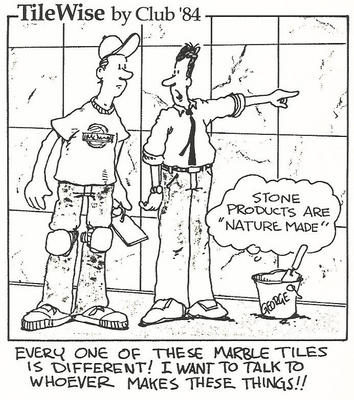

Natural Stone & Natural Stone Variation

Natural stone is a product of the earth, formed over millions of years through heat, pressure, and mineral deposits. Because of this, no two pieces are ever identical. Even when cut from the same block, stone can display dramatic shifts in veining, color tone, or texture. These natural variations are not defects; they’re part of what makes the material so special. The appeal of natural stone lies in its uniqueness; its organic imperfections are what give it character and charm.

Clients are often surprised when the stone installed in their home doesn’t look exactly like the showroom sample. This is completely normal. Samples represent just one piece of the puzzle; your final installation will feature a full spectrum of the stone’s unique characteristics. Consistency is not the goal, character and individuality are. What might be considered “imperfections,” such as fissures, veining, or mineral deposits, are markers of authenticity. While we always aim to balance tones during layout, natural stone is inherently varied, and some changes in tone or pattern are to be expected and celebrated.

Handcrafted Tile, Zellige, & Surface Irregularities

Handmade tile such as Moroccan Zellige, is prized for its imperfect, organic quality. Unlike machine-made ceramic, these tiles are hand-cut, hand-glazed, and wood-fired. This process introduces variation in shape, color depth, and surface texture. You’ll often see irregular edges, glaze pooling, pitting, crazing (fine surface cracks), and undulation across the surface.

This is not a flaw—it’s the essence of what makes handcrafted tile beautiful. These tiles tell a story of human touch and traditional craftsmanship. Because they are not uniform, grout lines will vary in width, and the surface won’t lay perfectly flat like a standard subway tile. Instead, the light will bounce off each one in a way that gives the installation depth and richness that can’t be replicated with mass production.

For clients seeking a highly polished or uniform finish, Zellige may not be the right fit. But for those who appreciate artistry and texture, it offers a timeless, character-rich finish that only gets better with age.

When it comes to finishing the edges of Zellige or other handcrafted tile, there are two primary approaches: using a trim piece like Schluter or mitering the tile edges. Each has a distinct aesthetic and practical purpose, so it all comes down to personal preference.

Mitered corners are a high-end detail where the edges of the tile are cut at a 45-degree angle and joined to create a clean, seamless outside corner. This method maintains the handcrafted look without introducing a modern trim element. It’s a popular choice for clients who want a more traditional or artisan feel, especially in installations where the tile is meant to be the focal point. That said, it does require precision and a bit more labor, which can affect the overall cost.

On the other hand, Schluter edging or other metal trim offers a more modern and streamlined look. These pieces come in a variety of finishes (like brushed nickel, matte black, or brass) and provide a durable, low-maintenance solution for protecting tile edges. They can be especially useful when working with irregularly sized or fragile tile, as they help reinforce the edge without the need for delicate mitering. Schluter is also a great choice if you love the irregular look of the tile face but prefer a more finished or uniform edge.

Ultimately, the choice comes down to style and budget. Mitering emphasizes craftsmanship and cohesion, while Schluter adds a contemporary design detail and practical edge protection. Both are valid, just different ways to finish a beautiful tile installation.

Natural Stone Versus Manufactured Stone

Natural stone is sourced directly from the earth, while manufactured stone is made from cement, aggregates, and pigments, molded to replicate the look of real stone. Both have their place in modern construction, but they differ in performance, aesthetics, and longevity.

Natural stone is inherently unique. It carries geological history in every slab, with layered movement, color shifts, and mineral veining that’s impossible to mass-produce. It tends to be heavier, more durable, and when properly maintained can last generations.

One common point of confusion is quartz vs. quartzite. While their names sound similar, they are completely different materials. Quartzite is a natural stone formed from sandstone and intense heat and pressure within the earth, resulting in a hard, dense surface with beautiful, unpredictable veining. Quartz, on the other hand, is a manufactured surface made from crushed natural quartz combined with resins and pigments to create a consistent, non-porous material. Quartz tends to be lower maintenance and more uniform in appearance, while quartzite offers the raw beauty and uniqueness of natural stone, but usually requires sealing and a bit more care.

When choosing between natural and manufactured stone, it’s important to consider both budget and expectations around appearance and maintenance. Manufactured options offer consistency, ease of care, and affordability. Natural stone offers authenticity, variation, and a timeless quality that simply can’t be replicated. Neither is “better,” just different, with their own strengths depending on the space and the goals of the project.

Color Movement & Variation in Plaster

Plaster finishes, especially Venetian plaster and lime-based plasters, are dynamic by nature. They’re not flat or static like paint. These materials are applied in layers using hand trowels, with subtle shifts in pressure, angle, and timing that produce rich, multi-dimensional surfaces.

As the plaster cures, it undergoes chemical changes that contribute to tonal variation. You might see areas of soft clouding, depth, or warmth that weren’t visible during application. These fluctuations are known as color movement, and they’re a hallmark of quality craftsmanship, not something to be corrected.

In certain lighting, this movement becomes even more pronounced. The finish may appear different throughout the day, depending on the angle of light or time of year. This interaction with the environment is intentional and gives the material its luxurious, ever-changing character.

Because of this, no two walls will ever look exactly the same. And while samples give a general sense of tone, they cannot fully capture the movement and texture of a finished wall. If you value consistency over character, plaster may not be the right material, but for those seeking elegance, softness, and depth, there’s nothing else like it!

Porcelain Versus Ceramic Tile

At a glance, porcelain and ceramic tiles may appear similar, but they have important differences that affect durability, appearance, and cost.

Porcelain is made from finer, denser clay and fired at a higher temperature than ceramic, making it harder, more water-resistant, and more suitable for high-traffic or wet areas like bathrooms, mudrooms, or patios. Many porcelain tiles are full body, meaning the color runs through the entire tile, which can be helpful if the surface ever chips. Because of its strength and durability, porcelain is often more expensive and can be more difficult to cut and install.

Ceramic tile, while also durable and long-lasting, is more porous and better suited for dry, lower-traffic areas like backsplashes or powder rooms. It tends to be easier to work with and may offer a slightly lower price point. However, ceramic can chip more easily on the edges, and the color underneath is often different from the glazed surface, which can make chips more visible.

It’s also important to understand that variation is normal across both types of tiles. Size, thickness, and surface flatness can vary slightly between pieces, especially with handmade or artisanal lines. These characteristics are not flaws—they are industry-accepted tolerances. Similarly, lippage (where the edge of one tile is slightly higher or lower than the one next to it) is a natural part of tile installation and is even more likely with larger format tiles or tile with some inherent bowing.

While grout joints help accommodate these differences, a perfectly flat or seamless look is not guaranteed. We recommend clients view multiple pieces before install and understand that what’s visible in a single showroom sample may not reflect the full range of tone or shape.

Understanding Industry Standards & Visual Expectations

In residential remodeling, quality is measured not only by precision and craftsmanship, but also by what’s reasonable and realistic. Industry standards exist to guide both installers and clients in understanding what’s acceptable, especially for finishes like tile, paint, cabinetry, drywall, and flooring.

One of the most referenced standards comes from the Tile Council of North America (TCNA) and NKBA guidelines, which state that finished surfaces – such as tile walls or painted cabinetry – should be evaluated from a normal viewing distance, typically 3 feet away under normal lighting conditions. “Normal lighting” means the general ambient light used in a typical home, not harsh or directional lighting that can highlight minor surface flaws. This means that minor surface imperfections (like a small seam, slight color variation, or minute texture change) that are not visible from this distance are considered acceptable.

These standards help ensure fairness and clarity during final walkthroughs. They take into account the fact that many materials, especially natural or hand-applied ones, are not intended to be viewed under magnification or harsh directional light. Even the most meticulous installation will show some minor irregularities when inspected up close or under specialty lighting.

In short, perfect doesn’t mean flawless. It means appropriate for the material, space, and lighting. Our goal is always to deliver a beautiful, lasting result that aligns with both aesthetic goals and practical expectations.

When remodeling an existing home—especially one that’s older—it’s important to understand that we are working within the constraints of the original construction. Very few homes are perfectly plumb, level, or square. Walls may bow, floors may slope, and framing irregularities may not be visible until demolition is complete.

While we always strive for clean lines, level surfaces, and precise finishes, we are often blending new materials and modern expectations into older frameworks. In these cases, absolute perfection isn’t always achievable without extensive reconstruction that may be outside the scope or budget of the project.

For example:

- New baseboards may highlight existing floor unevenness

- Tile may have visible grout line variation due to wall bowing

- Cabinets may have small gaps if walls aren’t perfectly square

- Millwork may not sit flush in corners with settled framing

These kinds of challenges are extremely common and are not a result of poor workmanship, but rather the natural realities of remodeling. Where possible, we’ll offer solutions (like shimming, trim adjustments, or strategic transitions), but not every flaw can or should be fully corrected if it doesn’t affect function or safety.

Our work is held to the professional industry standard of quality and finish, meaning that completed work should appear consistent and appropriate when viewed from a normal distance and under standard lighting, not under a magnifying glass, harsh spotlight, or when compared to factory-perfect conditions.